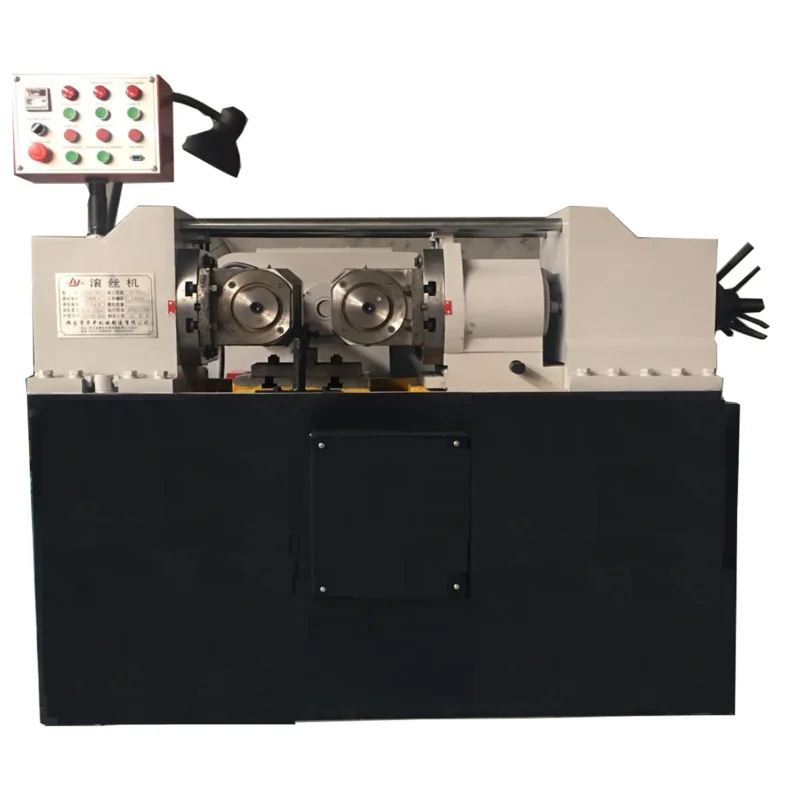

Machine multifonctionnelle de traitement de barres d'armature pour tubes en cuivre haute performance, petite machine de redressage et de découpe de fils

ر.س1,636.95

Machine multifonctionnelle de traitement de barres d'armature pour tubes en cuivre haute performance, petite machine de redressage et de découpe de fils

Steel wire straightening and cutting machine is a kind of steel processing equipment, mainly used for straightening and cutting various steel materials, such as ordinary carbon steel, hot-rolled round steel, rebar, cold-rolled steel bars, etc.

Straightening and cutting machines can be widely used in bridges, pile foundations, building construction, standardized

construction, steel processing plant, and other industries.

Description des produits

Main Features:

1. steel wire straightening and cutting machine is widely applied to the straightening and cutting of steel rebar in the

engineering construction and steel processing sector.

2. After the steel bar straightening and cutting machine, the surface of the modulated steel bar is basically non-scratched, the strength loss is small, the straightness is good, the operation is simple and the adjustment is convenient.

3. Full automatic numerical control panel so that the steel rebar can be straightened and cut at the same time.

4. Hydraulic (double-tube and double-knife) cutting, no clipper, more precise, more silent.

5. High-quality straightening box with CR12 straightening wheels.

6. Upgraded meter calculated wheel makes the rebar length more accurate.

7. Microcomputer control, automatic straightening, automatic ruler setting, and automatic cut-off. Start and shut down by remote control within 30m.

8. Multiple batches of simultaneous input length and quantity, computer storage memory.

9. Powerful international standard pure copper motor.

Présentation du produit

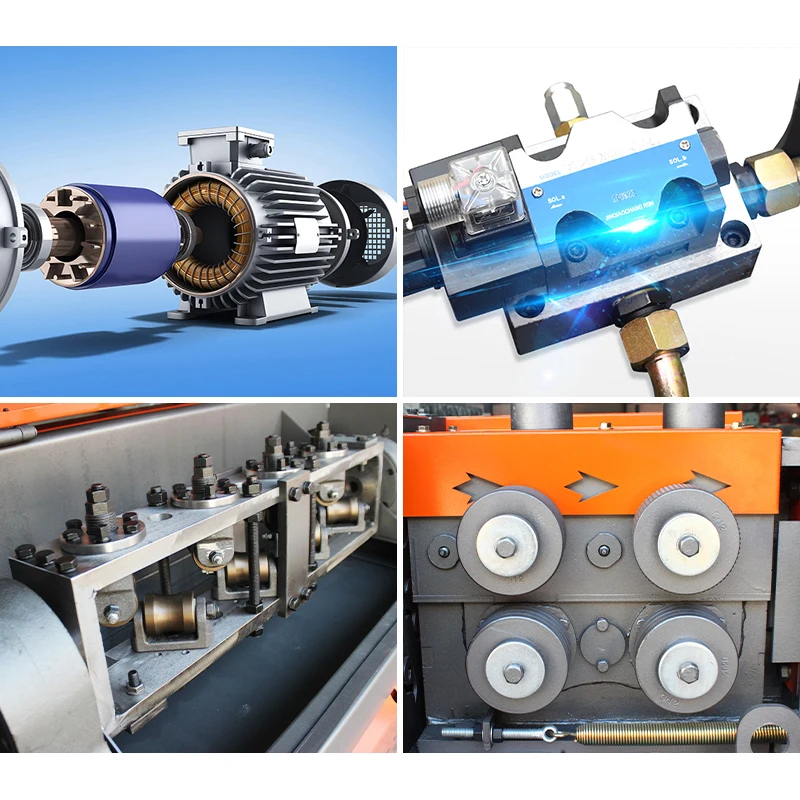

Détails Images

1. Length recording wheel: Electromagnetic control, high-quality length calculation wheel, small cutting error

2. Digital control panel: Microcomputer control, automatic straightening, automatic ruler setting, and automatic cut-off. Straightening cutting machine makes mechanical cutting more precise and the error is controlled within ±0.2mm.

3. High-quality hydraulic system: Bar cutting straightening machine provides sufficient hydraulic power to the cutter to make the cut-off port smoother

4. Preset wheel and front traction wheel: The feeding speed of pre-straightening and power traction is fast, the quality is good, and the efficiency of the next main straightening process is high. Two motors perform their own duties, traction, straightening, and hydraulic cut-off. High straightening efficiency.

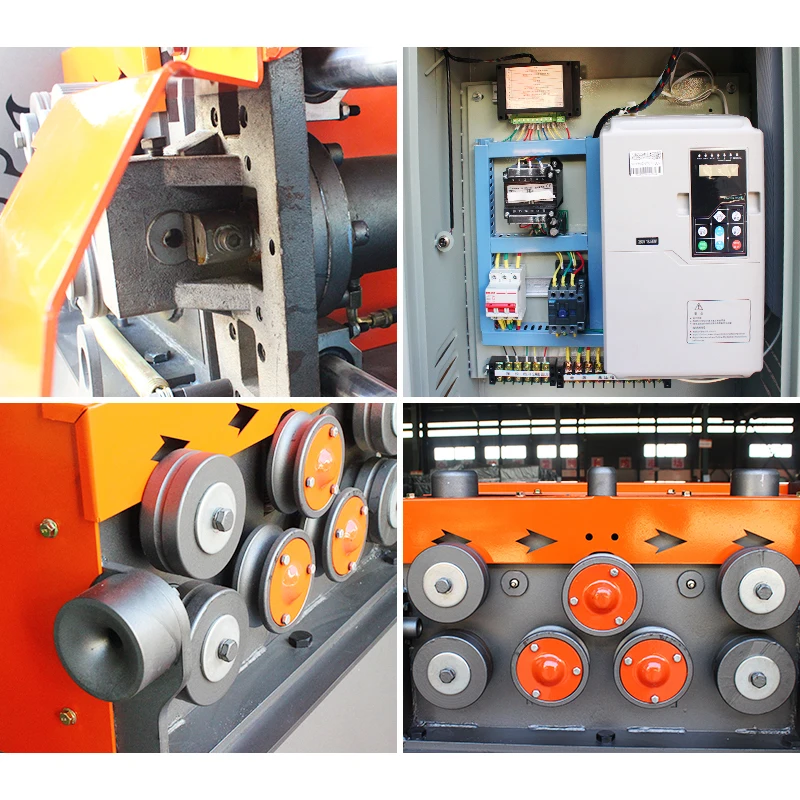

Feeding Wheel

Double-row four-wheel feeding mouth, convenient for feeding steel wire, not easy bending. Improving work efficiency.

Straightening Structure Assembly

700mm alloy straightening structure, Cr12MoV straightening wheel durable and wear-risistance, matched with RENBEN bearing, servicelife improving by 200% compared with similar products.

Metering Wheels

Cr12MoV metering wheel, matched with RENBEN bearing, stable running, highly accurate metering wheels, reducing the cutting error.

Hydraulic Cutting

Thickened steel structure matched with high strength wear-resistant hard blades, fast cutting, not easy to lose.

Hydraulic Oil Cylinder

It adopts a hydraulic 32Mpahigh-pressure gear pump, improving the service life by 20%-30%

Oil Tank & Electromagnetic Valve

A high-quality electromagnetic valve with a sealed oil tank prevents it from leakage, and internal leakage is easily under control. it’s easy and fast to control oil.

Electric Control Cabinet

The computer system adopts German imported chips, which can set 0-99 batches, and batches can be inserted during operation, more humanized. The contractor, the key part of the control box adopts the Chinese famous brand ZHENGTAI ELECTRIC, safer.

Emballage du produit

Paquet d'exportation 1 unité a été emballée dans un cadre en fer puis emballée avec 5 couches de carton ondulé. 4 bandes ont renforcé le carton. L'emballage fixe garantissait que les machines n'étaient pas endommagées pendant le transport

FAQ

Q1. What can we do if there are problems with the products?

R : Nos ingénieurs analyseront le problème pour vous et trouveront la meilleure solution. Si des problèmes surviennent dans le délai garanti, nous pouvons remplacer les composants gratuitement. Nous avons des revendeurs dans certains pays, pour certains problèmes techniques que vous ne pouvez pas résoudre vous-même.

Q2. Quel est le délai de livraison de vos produits ?

R : Une fois que nous avons promis le délai de livraison, nous ferons de notre mieux pour le respecter. Des procédures spéciales telles que l'inventaire d'urgence seront utilisées pour maintenir votre approvisionnement ininterrompu des produits.

Q3. Is there any guarantee for your products?

R : La plupart de nos produits bénéficient d’une garantie d’un an (pour les pièces principales).

Q4. Comment pouvez-vous contrôler la qualité de vos produits ?

A: Quality is always considered the most important part of our manufacturing process. All of our products come under a strict quality control system from raw material inspection, component inspecting,semi-finished product inspecting, performance test of finished products, to random inspection before delivery.

MÉCÈNE IACULIS

Vestibulum curae torquent diam diam commodo parturient penatibus nunc dui adipiscing convallis bulum parturient suspendisse parturient a.Parturient in parturient scelerisque nibh lectus quam a natoque adipiscing a vestibulum hendrerit et pharetra fames nunc natoque dui.

ADIPISCING CONVALLIS BULUM

- Vestibulum penatibus nunc dui adipiscing convallis bulum parturient suspendisse.

- Abitur parturient praesent lectus quam a natoque adipiscing a vestibulum hendre.

- Diam parturient dictumst parturient scelerisque nibh lectus.

Scelerisque adipiscing bibendum sem vestibulum et in aaa purus lectus faucibus lobortis tincidunt purus lectus nisl class eros.Condimentum a et ullamcorper dictumst mus et tristique elementum nam inceptos hac parturient scelerisque vestibulum amet elit ut volutpat.

Fournitures d'ingénierie

Fournitures d'ingénierie

MACHINES À SOUDER

MACHINES À SOUDER

OUTILS DE MESURE

OUTILS DE MESURE

MACHINES POUR L'ACIER D'ARMATURE

MACHINES POUR L'ACIER D'ARMATURE

Engins routiers

Engins routiers

Avis

Il n’y a pas encore d’avis.