Pompe à eaux usées submersible à haut débit WQ 1,1 kW 220 V pour eaux usées sales, boues et boues

ر.س764.83

Description des produits

WQ1 pump usually refers to a submersible sewage pump, which is a type of submersible sewage pump mainly used to transport sewage and pollutants containing solid particles. The following are some key features and applications of WQ1 pump:1. * * Structural features * *: The WQ1 pump consists of a water pump, a seal, and an electric motor. The electric motor is located on the upper part of the electric pump and can be a single-phase or three-phase asynchronous motor. The double end mechanical seal is used between the water pump and the motor, which has the advantages of compact structure, large flow rate, and high efficiency.2. * * Passing Capacity * *: The WQ1 pump adopts a unique single or double blade impeller structure, effectively improving the sewage passing capacity. It can pass through fiber material 5 times the pump diameter and solid particles about 50% of the pump diameter.3. * * Mechanical Seal * *: The mechanical seal of WQ1 pump adopts a new type of hard and corrosion-resistant material, such as titanium tungsten, which can ensure safe and continuous operation of the pump for more than 8000 hours.4. * * Automatic Protection * *: The sealing oil chamber of the WQ1 pump is equipped with a high-precision anti-interference leakage detection sensor, and a thermosensitive element is embedded in the stator winding to provide automatic protection for the water pump motor.5. * * Control and Installation * *: The WQ1 pump can be equipped with a fully automatic control cabinet to automatically protect the pump from water leakage, leakage, overload, and overheating. It can also be equipped with a dual rail automatic coupling installation system, simplifying the installation and maintenance process.6. * * Application Scope * *: WQ1 pump is suitable for various occasions, including chemical, petroleum, pharmaceutical, mining, papermaking industry, municipal engineering, construction sites, etc. It is also suitable for conveying granular sewage and sewage, as well as pumping clean water and corrosive media.7. * * Usage conditions * *: WQ1 pump is suitable for three-phase AC power supply with rated motor voltage of 380V and frequency of 50Hz. The conveying medium temperature does not exceed 40 ℃, the medium pH value is between 4-10, the solid volume ratio is below 2%, and the medium density is less than 1.2 × 10 ^ 3 Kg/m ^ 3.The design of WQ1 pump focuses on high efficiency, energy conservation, anti winding, non clogging, automatic installation and control, making it very popular in the field of sewage pumps.

Spécification

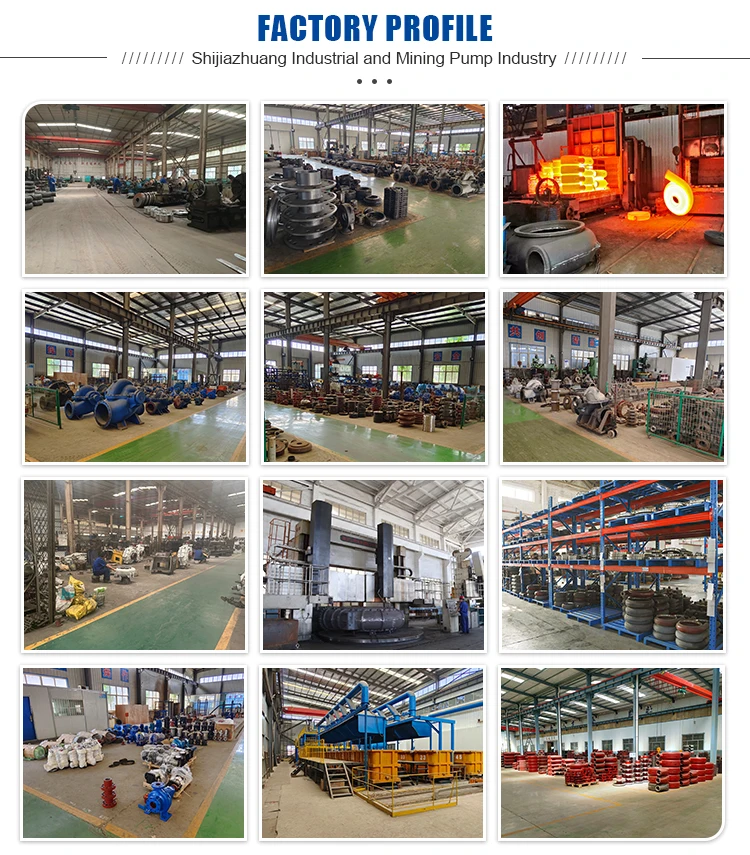

Profil de l'entreprise

Exposition

Packing&Delivery

FAQ

A1. What is the main working principle of a centrifugal pump?Q1. The electric motor drives the impeller to rotate at high speed, generating centrifugal force on the liquid. The liquid is thrown into the side channel and discharged outside the pump, or enters the next stage impeller, thereby reducing the pressure at the inlet of the impeller and forming a pressure difference with the pressure acting on the suction liquid. The pressure difference acts inside the liquid suction pump, and due to the continuous rotation of the centrifugal pump, the liquid is continuously sucked in or discharged.A2. How many types of transmission connections are there between pumps and motors?Q2. There are three types: belt drive, gearbox drive, and direct motor linkage.A3. What is the phenomenon of voids?Q3. The cavitation phenomenon is the formation of vapor chambers (“bubbles” or “voids”) in liquid, which is the result of the inlet pipe diameter being smaller than the flow rate of the pump. These cavities are formed by the fluid characteristics and physical properties of the pump system (such as available pressure, temperature, pump speed, etc.). The cavitation phenomenon is prone to generate noise and premature wear of the pump.A4. What is gear pump internal leakage?Q4. Internal leakage of a gear pump refers to the situation where some fluid on the pressure side flows back to the inlet side through the gear clearance, affecting efficiency. Internal leakage is a common problem among all gear pumps. Precision grade micro gear pumps have relatively small internal leakage, making it easier for low viscosity fluids to pass through these small gaps. Therefore, pumps are more efficient in thicker or viscous fluids.-The starting ability varies depending on the pump and depends on various factors, including fluid viscosity, pipeline size, steam pressure, speed, and whether the pump is operating wet or dry.What affects the lifespan of pumps and motors?-Many factors can affect the service life. The key issues to consider are the number of on/off cycles, operating speed, load (pressure), and fluid contamination.What is the noise level of the pump?-The noise level depends on the installation of the pump, the speed of the motor, and the type of fluid. When the pressure difference is 3 bar and the speed is 3000 rpm, the reference value of the gear pump at 1 meter is 55 dB.

MÉCÈNE IACULIS

Vestibulum curae torquent diam diam commodo parturient penatibus nunc dui adipiscing convallis bulum parturient suspendisse parturient a.Parturient in parturient scelerisque nibh lectus quam a natoque adipiscing a vestibulum hendrerit et pharetra fames nunc natoque dui.

ADIPISCING CONVALLIS BULUM

- Vestibulum penatibus nunc dui adipiscing convallis bulum parturient suspendisse.

- Abitur parturient praesent lectus quam a natoque adipiscing a vestibulum hendre.

- Diam parturient dictumst parturient scelerisque nibh lectus.

Scelerisque adipiscing bibendum sem vestibulum et in aaa purus lectus faucibus lobortis tincidunt purus lectus nisl class eros.Condimentum a et ullamcorper dictumst mus et tristique elementum nam inceptos hac parturient scelerisque vestibulum amet elit ut volutpat.

Fournitures d'ingénierie

Fournitures d'ingénierie

MACHINES À SOUDER

MACHINES À SOUDER

OUTILS DE MESURE

OUTILS DE MESURE

MACHINES POUR L'ACIER D'ARMATURE

MACHINES POUR L'ACIER D'ARMATURE

Engins routiers

Engins routiers

Avis

Il n’y a pas encore d’avis.